Motorcycle Chains and Sprockets: The Need-to-Knows – Part One

Motorcycle Chains and Sprockets: The Need-to-Knows – part one.

Every motorcycle has a final drive system that transfers power from the engine and gearbox to the rear wheel. Of the three methods used a chain and sprockets is the most common. Shaft drive and belt drive systems offer advantages, but they also have their drawbacks, and like most things in life and on motorcycles everything is a compromise. The chain and sprockets have a hard life and are among the most abused components on a motorcycle, not only by the bike itself due to the forces put on it, but also sometimes by the owner, some of whom are negligent in the amount of care they give. Caring for your chain and sprockets is not difficult or expensive, and doing so will massively increase their life.

Here in part one of our two-part feature on chains and sprockets we look at chain and sprocket types and sizing and the effects of sprocket size on the gearing ratio. In part two we look at how to take care of and maintain your chain and sprockets.

CHAIN TYPES, CONSTRUCTION AND SIZING

Types:

Chains either come with sealed links or with unsealed links. Manufacturers fit sealed link chains as standard equipment on most modern motorcycles, while chains with unsealed links are used on older bikes and some small capacity bikes. The difference in a sealed link is that grease is applied between the pins and the bushes when the chain is manufactured, and seals are fitted to keep the grease in and dirt and water out. Unsealed links create little friction when rolling, but they need more frequent lubrication and will usually wear quicker than sealed links.

There are three types of seal used, O-ring, X-ring and Z-ring, and the letter refers to the cross-section shape of the ring. The O-ring type came first and is the most used, but for the racing world there is too much friction between the rings and the plates when the chain rolls. To overcome this they developed first the X-ring and then the Z-ring, both of which offer a reduction in the surface area in contact with the plates and so give less drag. In the real world the difference in performance is not noticeable, and all types do a very similar job of keeping the grease in and the dirt and water out. The difference is mainly in price and longevity. O-rings and therefore O-ring chains are cheaper, but X-rings will last a bit longer as there is less friction-bearing surface area to wear, and Z-rings are a further development of the X-ring.

Construction:

Each chain consists of a specific number of links that are joined by sideplates. Each link consists of two plates, two bushes and two hollow rollers. The bushes are a press-fit in the plates and the rollers fit over the bushes between the plates. The links are joined by sideplates, one with two pins that fit into the front bush on one link and the rear bush of the next link, thereby joining the links. An outer sideplate then fits over the outer ends of the pins that protrude from the links. The seals on sealed link chains fit between the sideplates and the links.

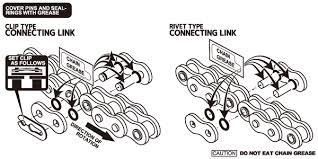

The ends of the chain are connected using a joining link, which is either a clip type link or a riveted type link. Clip links, used mainly on smaller capacity and less powerful bikes, have a spring clip that locates in grooves in the outer ends of the pins to secure the outer sideplate in place. The clip is easy to remove and fit and so the chain can be split easily. Riveted links, used on most bikes, are more secure than clip links, and you need a special tool to split the joining link when removing a chain and to secure it when fitting a new one.

Sizing:

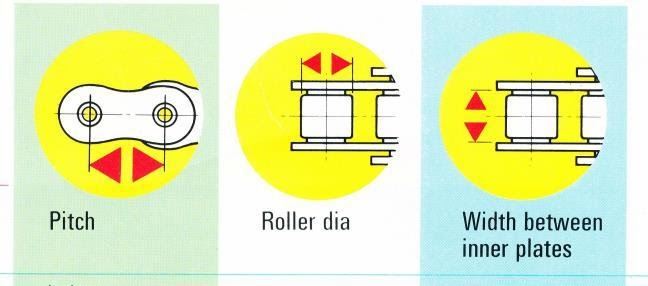

Chains come in several standardised sizes, and for each size the pitch, roller diameter and width are as shown in the table:

|

CHAIN SIZE |

PITCH mm |

ROLLER DIAMETER mm |

WIDTH mm |

|

420 |

12.70 |

7.75 |

6.35 |

|

428 |

12.70 |

8.81 |

7.75 |

|

520 |

15.88 |

10.16 |

6.35 |

|

525 |

15.88 |

10.16 |

7.85 |

|

530 |

15.88 |

10.16 |

9.53 |

|

532 |

15.88 |

11.10 |

9.53 |

The size of the chain required for a particular bike is determined at the design stage and the same size chain must always be fitted to the bike. Sprockets are sized to match the chain, so a bike running a 525 chain must have 525 sprockets, otherwise the rollers will not sit correctly between the sprocket teeth.

SPROCKETS, SPROCKET SIZING AND FINAL DRIVE GEARING

Sprockets and sprocket sizing:

Motorcycles have two sprockets, the front (drive) sprocket on the transmission output shaft, and the rear (driven) sprocket on the rear wheel. Most road bikes use steel sprockets, whereas racing bikes use lighter aluminium sprockets to reduce rotational mass, which saps power, and unsprung weight, which affects the action of the suspension, though they cost more and wear quicker. As an ideal compromise dual-metal sprockets that have an aluminium centre and a steel tooth ring riveted around it have been around for a while, though are only available as rear sprockets.

As previously mentioned, the front and rear sprockets are sized in terms of their thickness and the distance between the teeth and must match the size of the chain that runs around them. The front sprocket is always much smaller in diameter than the rear and for most bikes usually has around 14 to 18 teeth, and the rear sprocket usually has between 34 and 50 teeth, though there are some specialist off-road applications that may use smaller front sprockets and larger rear sprockets.

Final drive gearing

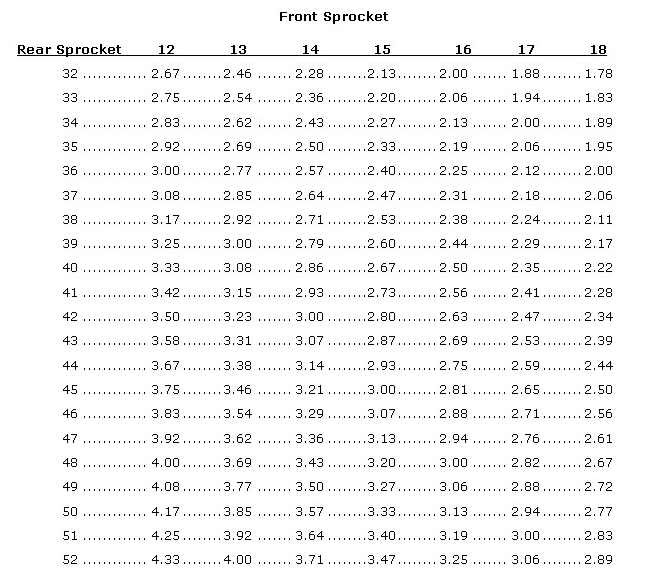

The relationship between the number of teeth on each sprocket is called the final drive gearing ratio and determines how much the rear sprocket turns in relation to the front sprocket. To calculate the ratio you divide the number of teeth on the rear sprocket by the number of teeth on the front sprocket as shown in the table below. This ratio is determined at the design stage to give the best overall gearing for the type of riding that the bike is designed for, but it is always a bit of a compromise as it will never be perfect for all riders and all situations. For that reason many riders change sprocket size to achieve gearing that is more suitable for their use. For example, a rider using a bike to commute on a dual carriageway or motorway may prefer to have fewer engine revs at cruising speed, giving better comfort and economy at the expense of acceleration, or to have a higher top speed. Conversely a rider in town or city traffic may prefer to have greater flexibility in lower gears to manage traffic and reduce the amount of clutch slipping in stop-start riding, or to increase acceleration.

To reduce engine rpm at a particular road speed or to increase top speed you fit a larger front sprocket or a smaller rear sprocket. This has the effect of making the rear wheel turn more for every turn of the front sprocket and is known as raising the gearing, though confusingly this lowers the ratio. To give greater flexibility at slow speeds and in traffic and to increase acceleration you fit a smaller front sprocket or a larger rear sprocket. This has the effect of making the rear wheel turn less for every turn of the front sprocket and is known as lowering the gearing though it raises the ratio.

Changing the final drive gearing on your motorcycle can be a matter of trial and error. It is difficult to know by how much you need to change it before you achieve the ideal set-up, and which sprocket you change is an important factor.

Front sprockets are usually available in one-tooth increments either side of the standard size, so if your standard front sprocket is 15 teeth you should be able to purchase a 14- and a 16-tooth alternative. Rear sprockets are often available in one-tooth increments, but sometimes only in two-tooth increments, either side of the standard size. How many alternatives are available depends on the demand from riders and the available supply from after-market dealers. The smallest gearing change you can achieve is by changing the rear sprocket by one tooth, if such a sprocket is available, though most riders will change by two teeth for a noticeable difference. Changing one tooth on the front sprocket is about the equivalent to changing three teeth on the rear, as shown in the table above.

One thing you must bear in mind when changing sprockets is how it will affect the length of the chain, and whether you will need to increase or decrease the number of links to remain within the adjustment limits of the swingarm.

To view the full range of MPW chains and sprockets go to https://motorcyclepartswarehouse.co.uk/engine-transmission/chains-belts-sprockets.html