Motorcycle Tyres: The Need-To-Knows - Part Three

Motorcycle Tyres: The Need-To-Knows – part three

When you consider the amount of work motorcycle tyres do and the responsibility they have, you may wonder how they cope. The material they are made of provides the grip that allows you to lay down large amounts of power and torque, lean over at extreme angles at speed, and stop safely with the brakes applied hard. That grip is the difference between pleasure and pain and needs to work well in a whole variety of conditions.

Without good tyres the abilities of the engine, suspension and brakes are irrelevant. Tyres are massively important, and thankfully a lot of them are good, really good, especially when you consider how much of each one is actually in contact with the road. Makes you wonder – how do they cope with that?

Here in part three of our three-part feature on tyres we look at tyre use and maintenance. In part one we look at tyre construction, compounds, and tread patterns, and in part two tyre selection.

Tyre use and maintenance:

Your safety while on a bike depends to some extent on the tyres, so it is worth taking care of them. They do not require much attention and are not hard to look after, so why so many people chose to ignore such a simple yet crucial thing as the pressure of the air inside them is beyond comprehension. And you need to be aware of and develop a feel for what your tyres are telling you, as they are the main provider of feedback on what is happening between them and the road.

New tyres:

You would imagine that when you pay the amount you do for motorcycle tyres from top makers such as Dunlop and Michelin you shouldn’t have to worry that they could be the cause of a crash at the first bend or roundabout. You expect them to be a massive improvement on your old rubber from the word go. But there are warnings about riding on new tyres that are given for good reasons.

Most manufacturers are now using Teflon-coated moulds rather than a releasing agent to ensure the tyre comes out of the mould easily, and so the need for care is reduced from that point of view, unless of course your tyre is one of the few that has had an agent applied. However, manufacturers still give new tyres a dark glossy finish, partly because some of the chemicals used in the curing process give them that finish, also because they believe that is how their customers want new tyres to look. The difficulty is in knowing for sure what applies to your new tyres, so a degree of caution is needed for all. You would think that the easiest and best thing to do would be to clean the tyre before you use it, but the use of any cleaning chemical could upset the balance of the compound and affect the tyre for its entire life. If anything, just use a clean dry cloth to wipe the tyre.

The best way to clean or scrub in a new tyre and lose the gloss is to get it up to its normal temperature by going for a long ride without pushing the tyre hard, but just making sure it gets properly warmed, as it is heat that is needed. You do not need to lean the bike far or weave around to get every bit in contact with the road as the heat will naturally radiate across the whole of the tread. Acceleration and braking are the best ways of getting heat into the tyre but be gentle at first until the tyre warms up, and gradually increase performance until the tyre is hot, and then you can start to lean a bit further. The best way of knowing when your tyre is warm and when it is hot is by feeling with your hands. How quickly it will warm up and therefore how far you need to ride depends on the tyre itself, the bike, the ambient temperature, the road surface temperature, the road surface texture, and so on.

Taking care on new tyres not only allows them to achieve optimal grip safely but also gives the rider the opportunity to learn the characteristics of the tyres. Even if they are of the same type and brand as the old ones their characteristics will differ purely because of age.

Tyre pressures:

Michelin's TPMS (tyre pressue mintoring system)

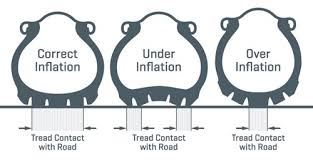

The air in your tyres gives and maintains their shape, is crucial to handling and wear characteristics, and helps the suspension soak up the initial shock from the many bumps and holes in our roads.

Keeping your tyres at the correct pressure is a fundamental yet important task and is crucial to all aspects of the performance of the tyre. Incorrect pressures will lead to poor handling and increased wear rates and means you will not get the best out of the other aspects of your bike such as the power, handling, and brakes. The correct tyre pressures are specified by the manufacturer in the motorcycle’s handbook and are often marked on a sticker on the swingarm, and those pressures are arrived at following a lot of testing and collaboration between bike and tyre manufacturers.

Checking your tyre pressure is easy but does require the use of an accurate gauge, and many, particularly those on garage forecourts, can be wildly inaccurate. Spend as much as you can justify on a well-reviewed gauge. Always check tyre pressure when the tyres are cold - as the tyre warms up the pressure increases, and the pressures specified by the bike and tyre manufacturers are always given for a cold tyre. This is another good reason not to use garage forecourt gauges as you will need to ride to the garage which will make your tyre warm and give you a false reading, by up to 7 psi if the tyre is very warm, and if you then deflate a warm tyre to the specified pressure it will actually be under-inflated.

Ideally you should check your tyre pressure before every ride, just to be sure, but this is not always practical. If not daily then at least once a week –a tiny leak due to a poorly sealing tyre valve, dirt or corrosion around the bead seat, or a slow puncture are all common occurrences. You must also be aware of changes in the weather as this will affect the pressure - cold weather will lower the pressure and hot weather will raise it.

Under inflated tyres overheat and cause tread surface damage, and the tread will not work efficiently and will wear out unevenly. Some say that reducing tyre pressures slightly in cold and wet weather helps to increase the contact patch and so increase the amount of grip, however it can actually cause the contact patch to reduce because the tyre deforms and the centre lifts away from the road. It is best to just stick to what is specified. However it is true to say that partially deflating tyres for green lanes and byways has its benefits, but you must be able to reinflate them to the correct pressure when you get back on tarmac. Over inflated tyres wear unevenly, affect the handling, and reduce the tyre’s ability to absorb shocks which can make the ride feel hard. However it is usually necessary to increase you rear tyre pressure when carrying a passenger and/or luggage, and your handbook will specify this.

If you are storing your bike over winter it is important to keep the tyres correctly inflated. If the tyres are under inflated they can get permanently out of shape. The alternative is to put the bike on stands so the tyres are off the ground.

Tyre wear and tread depth:

Tyres wear down with use and will of course eventually wear to the point that you must fit new ones. The legal minimum tread depth for a tyre used on any bike 50cc or over in the UK is 1mm across three-quarters of the tread width, and with visible tread remaining on the other quarter. For bikes under 50cc there must be some of the original tread visible across the whole width.

However, with this little amount of rubber left the tread will struggle to disperse water effectively, and consequently many riders sensibly consider 1.5 or even 2mm to be a safer wear limit. It is a simple job to measure the depth of the tread using either a dedicated tool, a ruler or a vernier caliper, and all tyres carry tread wear limit bars, which are small ribs of raised rubber set on the bottom of some of the tread grooves around the tyre. If the tread is worn so that these indicators are flush with the surface of the tyre you know the limit has been reached. You can identify the location of the indicators by looking for the letters TWI (for Tread Wear Indicator) marked on the shoulder or sidewall, or sometimes the manufacturer will use their logo, such as the Michelin man, instead. When you check your indicators be aware of the need for the tread to be across most of the tyre width, as you could have wear indicators that are below the tyre surface on the outer sections of the tread at the same time as exposed chord or fabric in the middle, especially if you ride on straight roads or don’t like leaning very much.

Using a tyre tread depth gauge

Tread wear limit bar

Rear tyres rarely wear evenly, and usually the extra wear in the centre of the tyre squares them off so the curved profile is no longer there. Front tyres do not square off in the same way, but cornering forces can create an unevenness between tread edges known as feathering or scalloping and are often more prone to this than rear tyres.

Tyres, particularly tubeless ones, can be hard to fit, so it is best to get a specialist to do this as they have the necessary tools and equipment and can balance the wheel afterwards. If you run tubeless tyres it is good practice to fit a new tyre valve at the same time, and if you run tubed tyres it is good practice to fit new inner tubes and rim tape at the same time, irrespective of how the old ones look. If you do fit your own tyres use a dedicated specialist tyre fitting lube to help them off and on the rim in preference to any other form of lube.

Puncture repair:

Some punctures can be repaired, and some cannot. If you do repair a puncture only ever consider it as a temporary fix to get you home or to a workshop, and fit a new tyre or inner tube as soon as possible.

There are no laws about puncture repair, just recommendations and guidance, to which common sense must be added. A British Standard for puncture repair exists under BS AU159F. Different manufacturers and dealers will give their own advice, but the BS recommendations are as follows:

- Repairs can only be made to the middle 25% of the tread area.

- All repairs must be made using a mushroom type plug fitted into the hole from the inside (which means removing the tyre), and must be bonded to the tyre by vulcanisation.

- No repairs can be made to punctures through the sidewall.

- No repairs can be made to any puncture on any tyre with a speed rating of Z or higher, that is over 150mph.

- For tyres with a speed rating from J to V, that is from 62 to 130mph, you can have one repair to a maximum diameter of 3mm.

- For tyres with a speed rating below J, that is less than 62mph, you can have two repairs to a maximum diameter of 6mm.

From a practical point of view it is very difficult to remove a tubeless tyre to do a roadside repair, especially on a bike with just a sidestand, and this is where the various products that allow repairs to be made to fitted tyres come into their own. There are repair kits that plug the hole from the outside and include compressed gas canisters to re-inflate the tyre, but these can only be used on tubeless tyres. There are also internal sealants such as Tyreweld that come in a can and are applied via the tyre valve, work well on all tyres, and are easier to apply and in my experience better than a cheap plug-type repair kit. There are also puncture prevention products, similar in form and application to those such as Tyreweld, that you put into a good tyre, and what they do is immediately seal any puncture that does occur, and supposedly on a permanent basis. It is a good idea to always carry your preferred form of repair around with you, particularly when venturing far from home.

Track days, tyre pressures and tyre warmers:

The MPW Race Department has a range of Tyre Warmers

If you take your bike to a track day and use your road tyres and are an average rider then there is no need to reduce tyre pressures. However, if you end up riding much harder on the track than you do on the road the tyres could overheat and if that is the case it is a good idea to reduce them a bit, but how much depends on how hot they are getting. To know if you need to reduce them and if so by how much, you must have an accurate pressure gauge with you and you must measure the pressure as soon as you come in from the track when the tyre is hot. As a rule of thumb if the front tyre exceeds 36psi when hot then reduce it to 36, and if the rear exceeds 42psi then reduce it to 42. If you become a track day regular/enthusiast/god or run a dedicated track bike with race tyres, you may end up reducing pressures further, but experience and good advice from fellow riders and the tyre suppliers will then be your guide. If you are riding the bike home just remember that if you have decreased the pressure for the track the tyres will become under-inflated as they cool down so you will need to re-inflate them before you leave.

More and more track day enthusiasts are using tyre warmers, and the good ones work well, but only if they are used correctly. If a tyre gets too hot it can affect the compound, and the overall performance of the tyre reduces, and any damage does not reverse when the tyre cools down. Only use warmers that have an in-built thermostatic cut-out switch that regulates and maintains the correct heat, and if possible get one with variable heat settings so you can select the correct one for the conditions and the tyres you are using. As a rule of thumb 80ºC is considered the optimum temperature and should be considered the maximum unless the tyre manufacturer specifically states otherwise for certain conditions. Tyre warmers are not for road use and will be of no benefit whatsoever.

To see the full range of tyres available from MPW, along with our selection of tyre accessories such as warmers, inner tubes, tyre levers and pressure gauges, browse the motorcyclepartswarehouse shop.